People with misalignments of the spine and/or pelvis, regardless of age, have a more or less pronounced reduced ability to sit and lie down. This applies not least to a large number of children and young people. Special transport shells are required to transport patients with pronounced deformities. One requirement for these shells is that the seating and lying surfaces are adapted to the deformities and designed in such a way that the patients can be transported while avoiding pressure peaks. Today, such shells have to be manufactured and customised by hand, which is a time-consuming process. The aim of the project is to develop an innovative concept with which modular transport trays can be customised to the needs of patients. At the same time, these transport shells are to be equipped with "smart materials" that can fulfil various functions and additional benefits. These include the monitoring of vital functions, options for regulating comfort (e.g. temperature) and the detection of pressure points on lying patients.

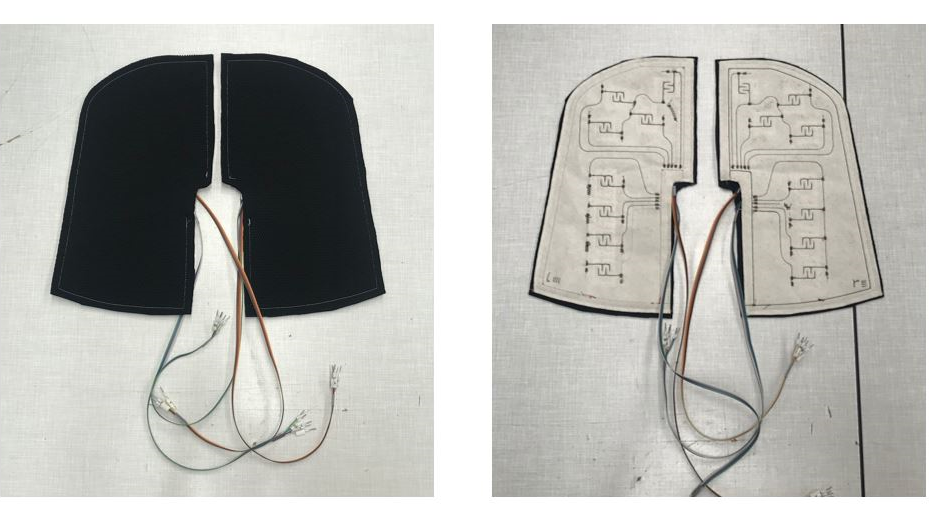

In the MoTraScha project, the partner Sindojan developed a seat that can adapt to the body shapes of children and young people with deformities and that can be used over a long period of time by growing patients. As one of the main tasks, a seat cover was developed at Reutlingen University which, due to the choice of material and special manufacture, is suitable for allowing adjustments to the shape of the seat without losing the fit of the cover. The second main task was to integrate so-called textile electronics into the seat, which allow various parameters to be read out or regulated. Textile sensors were developed for this purpose and integrated into the overall structure, which detect the pressure distribution in the buttocks area, the patient's temperature and a change in moisture in the seat cover in the event of wetting. The seat can also be temperature-controlled by integrating textile heating elements.

Industrial partner: Sindojan, OT Kiel

Project duration: 01.02.2021 - 28.02.2023